Mining Rock ore shiididda Kubbada Mill budada Machine

Mashiinnada kubbaddu waa qalab muhiim u ah dib-u-kicinta. Waxaa si weyn loo isticmaalaa sibidhka, alaabta silicate, qalabka dhismaha nooc cusub, wax dab-celis ah, bacriminta kiimikada, biraha madow iyo non-ferrous, galaas, ceramics iyo iwm. Kubbadeena shiidan kartaa macdanta ama alaabta kale ee la shiidi karaa midkood by habka qoyan ama by habka qalalan.

Kubbadu waxay ku habboon tahay ka-faa'iideysashada iyo shiididda dambaska duqsiga, dhagaxa nuuradda, ciid quartz, budada aluminium, budada dhuxusha, birta birta, ore, feldspar potassium, birta birta, birta birta, aluminium aluminium, silicon carbide, alumina, gangue dhuxul iyo qalab kale.

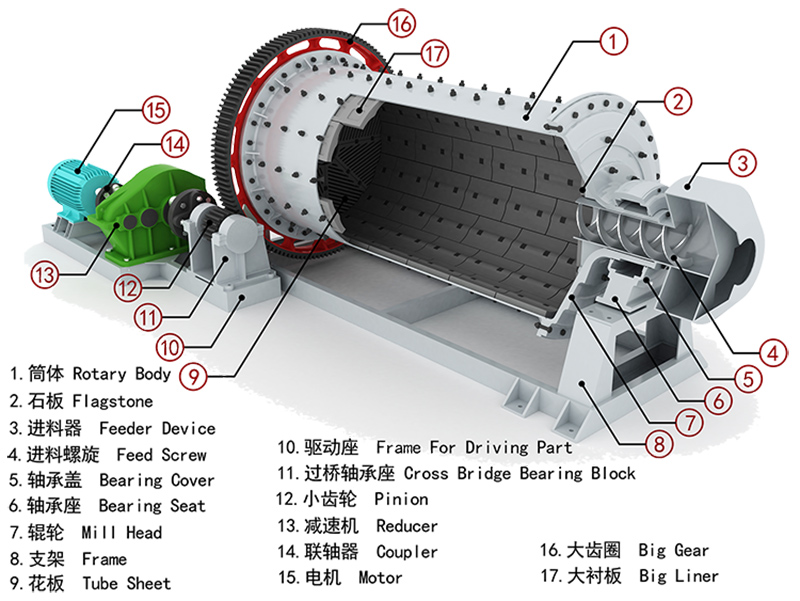

Mabda'a Shaqada

Qaybta ugu muhiimsan ee mishiinka kubbadda qoyan waa dhululubo leh dhexroor yar iyo dherer weyn oo si tartiib ah ugu wareegaya qalabka gudbinta. Maaddada waxaa lagu quudiyaa gelitaanka dhululubada iyo dhulka saamaynta kubbadda birta iyo macdanta iyo is-shiididda. Maaddaama maadada quudinta joogtada ah ay ugu wacan tahay, cadaadisku waxa uu ku riixayaa meesha laga baxayo, walxaha dhulkana waa laga siidaayaa godka dhululubada. Shabakadda lagu rakibay meesha wax lagu shido waxa lagu tiirsadaa daadinta qasabka ah. Dusha sare ee saxarka hoose ee dhululubada waxay yaraynaysaa shiididda macdanta, waxayna ka hortagtaa in kubbada birta ay soo baxdo. Isla xaaladaha wax-soo-saarka, awoodda wax-soo-saarka mashiinnada wax-soo-saarka ayaa ka weyn kuwa qulqulaya. Labada daraf ee jirku dhululubo waxay qaataan xajinta duubka halkii ay ka qaadan lahaayeen sibidhka, taas oo ah badbaado tamar badan.

Tilmaamaha Farsamada

| Nooca | Xawaaraha wareega | Miisaanka kubadaha | Cabbirka quudinta | Cabbirka wax soo saarka | Awood | Awoodda matoorka | Miisaanka |

| 900×1200 | 36 | 1.0 | ≤20 | 0.074-0.4 | 0.5-1.5 | 18.5 | 4 |

| 900×1800 | 36 | 1.5 | ≤20 | 0.074-0.4 | 1.1-3.5 | 22 | 4.8 |

| 900×3000 | 36 | 2.6 | ≤20 | 0.074-0.4 | 1.5-4.8 | 30 | 6 |

| Ф1200×2400 | 31 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 30 | 9.5 |

| Ф1200×4500 | 31 | 6.5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 4.5 | 13.1 |

| Ф1500×3000 | 27 | 6.8 | ≤25 | 0.074-0.4 | 2-6.3 | 75 | 16 |

| Ф1500×4500 | 27 | 10 | ≤25 | 0.074-0.4 | 3-9 | 110 | 19 |

| Ф1500×5700 | 27 | 13 | ≤25 | 0.074-0.4 | 3.6-11 | 130 | 24 |

| Ф1830×3000 | 25 | 10 | ≤25 | 0.074-0.4 | 4-11 | 130 | 25 |

| Ф1830×3600 | 25 | 12 | ≤25 | 0.074-0.4 | 4.3-12 | 155 | 32 |

| Ф1830×4500 | 25 | 15 | ≤25 | 0.074-0.4 | 4.5-16 | 155 | 33.7 |

| Ф1830×6400 | 25 | 21 | ≤25 | 0.074-0.4 | 6-17 | 210 | 38 |

| Ф1830×7000 | 25 | 23 | ≤25 | 0.074-0.4 | 6.5-18 | 210 | 43 |

| Ф2100×3000 | 23 | 13 | ≤25 | 0.074-0.4 | 5-15 | 180 | 32 |

| Ф2100×3600 | 23 | 16 | ≤25 | 0.074-0.4 | 6-17 | 210 | 35.8 |

| Ф2100×4500 | 23 | 20 | ≤25 | 0.074-0.4 | 7-21 | 245 | 42.6 |

| Ф2100×7000 | 23 | 31 | ≤25 | 0.074-0.4 | 8-25 | 280 | 55 |